◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。

在当今制造业与物流业迅猛发展的背景下,企业面临着前所未有的挑战与机遇。利元亨智能仓储物流自动化系统以其卓越的技术优势,成为众多企业提高仓储效率、降低运营成本的理想选择。作为该系统的核心组件之一,利元亨穿梭车系列设备凭借其高精度定位能力和高效的货物存取效率,在各类仓库和物流中心中发挥着至关重要的作用。利元亨穿梭车能够在设定路径上以最高300m/min的速度进行快速移动,并通过先进的定位系统实现对货物的精确识别与定位,确保每次存取操作的准确无误。

双向多层穿梭车

立体存储,空间优化

01

双向多层穿梭车是利元亨为应对现代仓库中高密度存储需求而设计的创新型产品。它不仅具备双向行驶能力,还能够实现垂直方向上的自动换层,这意味着它可以充分利用仓库内的三维空间资源,大幅减少传统仓储模式下通道所占的空间。这种穿梭车采用模块化设计,可根据实际需要灵活调整层数与布局,支持从单一货架到复杂多层立体库的应用场景转换。测试结果显示,在相同面积内,使用多层双向穿梭车可增加约40%的有效存储容量,显著提高了空间利用率。

四向多层穿梭车(料箱式)

灵活调度,高效拣选

02

针对高密度存储环境中物料快速拣选的问题,四向多层穿梭车(料箱式)提供了一个完美的解决方案。借助智能化调度算法,它们能迅速响应订单需求,将所需物料从密集存储区直接送至拣选工作站或出库口,大幅缩短出库时间。实验数据显示,与传统人工拣选相比,使用四向多层穿梭车后的拣选效率提高了近5倍,极大地提升了物流中心的整体运作效率。

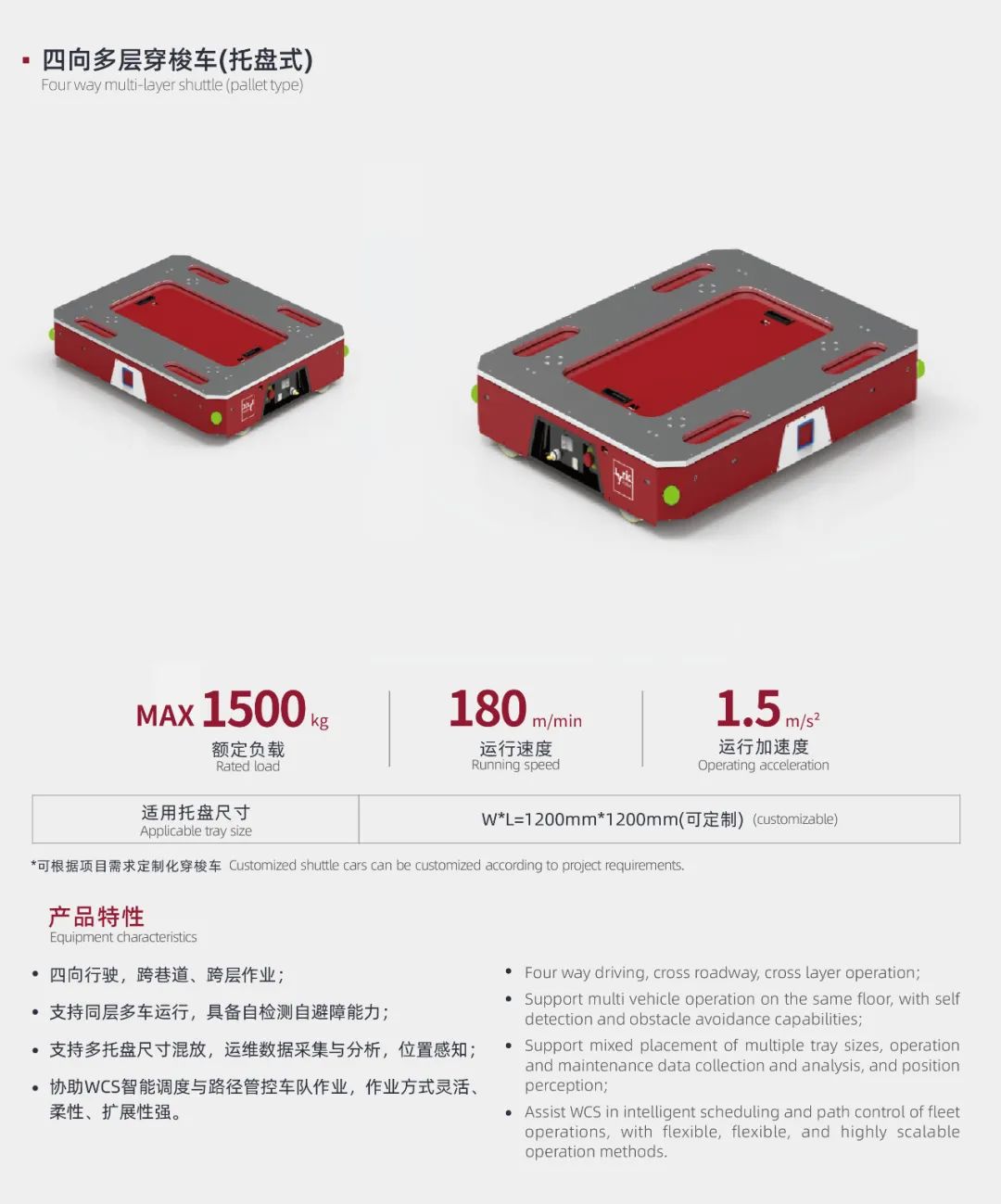

四向多层穿梭车(托盘式)

稳定承载,安全可靠

03

与料箱式穿梭车的轻载特性不同,四向多层穿梭车(托盘式)更加专注于重载物品的安全运输。该类型穿梭车配备了加固底盘设计和多重安全保障机制,确保即使在高速运行状态下也能保持出色的稳定性。此外,其独特的托盘交换功能使得在同一系统内可以同时处理多种尺寸规格的托盘货物,满足不同行业对于大件物品存储及搬运的需求。

子母穿梭车

协同作业,扩展性强

04

为了适应更大规模的仓储自动化需求,利元亨推出了子母穿梭车这一创新解决方案。母车作为整个系统的指挥中枢,负责与多个子车之间的信息交互及任务分配,通过无线通信技术实现了对子车集群的实时监控与管理。这种设计不仅显著增强了系统的灵活性和扩展性,还能根据业务量动态调整作业单元数量,从而达到最优资源配置。统计显示,在大型物流中心应用案例中,子母穿梭车系统可使整体吞吐量提升超过60%,为企业带来了显著的经济效益和竞争优势。

利元亨立足客户需求、解决客户痛点,不断加快仓储市场的布局和拓展,在核心技术及制造要求方面,以智慧化技术手段构建高精度的现代化物流服务模式。实现了智能仓储的标准化、智能化、无人化、精细化管理,持续驱动制造业智能化高速发展,助力新能源行业头部企业实现精益化生产!

【 Intelligent Revolution 】Lyric Intelligent Warehousing: How to enhance the competitiveness of enterprises with shuttle cars

Under the background of the rapid development of manufacturing and logistics industries, enterprises are facing unprecedented challenges and opportunities. With its excellent technical advantages, Lyric intelligent warehousing and logistics automation system has become an ideal choice for many enterprises to improve warehousing efficiency and reduce operational costs. As one of the core components of the system, the Lyric shuttle series plays a vital role in various warehouses and logistics centers with its high-precision positioning capabilities and efficient cargo access efficiency. The Lyric shuttles can move quickly on the set path at speeds of up to 300m/min, and achieve accurate identification and positioning of the cargo through the advanced positioning system to ensure the accuracy of each access operation.

Bidirectional multi-layer shuttle: three-dimensional storage, space optimization

The bidirectional multi-layer shuttle is a Lyric's innovative product designed to meet the demands of high-density storage in modern warehouses. It not only supports bidirectional movement but also enables automatic vertical layer switching, which allows full utilization of a warehouse’s three-dimensional space and significantly reduces the space traditionally occupied by aisles. The shuttle features a modular design, enabling flexible adjustments to the number of levels and layout based on actual needs, supporting applications from single shelving units to complex multi-level storage systems. The test results show that the use of multi-layer bidirectional shuttles can increase the effective storage capacity by about 40% in the same area, significantly improving space utilization.

Four-way multi-layer shuttle (for totes): flexible scheduling, efficient sorting

The four-way multi-layer shuttle (bin type) provides a perfect solution to the problem of fast material sorting in high-density storage environments. These shuttles are able to move freely in four directions, both horizontal and vertical, and are suitable for intensive tank storage systems. With intelligent scheduling algorithms, they can quickly respond to order needs and transfer the required materials directly from the dense storage area to the picking workstation or the exit, greatly reducing the picking time. The experimental data show that compared with the traditional manual picking, the picking efficiency after using the four-way multi-layer shuttle is nearly 5 times higher, which greatly improves the overall operating efficiency of the logistics center.

Four-way multi-layer shuttle (for Pallets) : stable load, safe and reliable

Unlike the light load characteristics of the tote-type shuttle, the four-way multi-layer shuttle (for Pallets) is more focused on the safe transportation of heavy loads. This type of shuttle is equipped with a reinforced chassis design and multiple safety mechanisms to ensure excellent stability even at during high-speed operations. In addition, its unique pallet exchange function allows the system to handle multiple sizes of pallet cargo in the same system at the same time, meeting the storage and transportation needs of large items across different industries.

Mother-Child Shuttle: collaborative operation, High scalability

To meet the growing demands of larger scale warehouse automation, Lyric has introduced an innovative Mother-Child Shuttle solution. Mother shuttle serves as the command center of the whole system, responsible for the information interaction and task allocation among multiple child shuttles, through pairs of wireless communication technology to achieve the real-time monitoring and management of shuttle clusters. This design not only significantly enhances the flexibility and scalability of the system, but also dynamically adjusts the number of work units according to the volume of business, so as to achieve the optimal resource allocation. Statistics indicate that in large logistics centers, the Mother-Child shuttle system can increase the overall throughput by more than 60%, which brings significant economic benefits and competitive advantages for enterprises.

Lyric is committed to understanding customer needs and addressing pain points, continuously acceleration its expansion in the warehousing market, Lyric builds a high-precision modern logistics service model with intelligent technologies in terms of core technology and manufacturing requirements. This approach has achieved standardization, intelligent, unmanned, and fine management of intelligent warehousing, continuously driving the rapid development of intelligent manufacturing, and helping the leading enterprises in the new energy industry in achieving lean production!

◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。

工作时间:8:00-18:00

电子邮件

扫码二维码

获取最新动态